Porous Chuck (Vacuum Chuck)

Stable suction is achieved by using porous ceramics.

The pore diameter of the porous body can be selected and manufactured in the desired size.

About Porous Chuck (Vacuum Chuck)

A porous chuck is a product that adsorbs and fixes thin and flat materials without deformation or damage. Air is drawn from the intake hole of the porous body (porous) to vacuum and fix the workpiece.

It can fix fine, ultra-thin, and long workpieces, which are not easy to use with vacuum or magnetic chucks, and it can handle a variety of materials because it works with non-magnetic materials.

In the semiconductor manufacturing process, it is used to cut thin silicon wafers without damage by holding them flat as well as for measuring and inspection equipment because it can adsorb films without any adsorption marks.

Features of Porous Chuck

- Porous ceramic plate with uniform pore

- High abrasion and heat resistance and no dust generation from the inside of porous ceramics

- Pore diameter is 2μm with partial adsorption

- Uniformly adsorbs thin glass and film workpieces without deformation

- Partial adsorption is possible / Only one adsorption plate is required

- Not likely to produce gas even in a vacuum

- Light (Specific Gravity 1.6 - 1.89)

Application Examples

Taking advantage of its feature of adsorbing and fixing workpieces and objects to be measured, it is being considered for application in various fields such as inspection and measurement equipment.

- Adsorption table (dicing saw, grinder, polisher, etc.)

- Heater Table (bonding machines, etc.)

- Spinner table (dicing saw, resist coating equipment, etc.)

- Table for inspecting and manufacturing film, etc.

Planar smoothness and special manufacturing methods provide superior adsorption and durability, ensuring high productivity and reliability in manufacturing processes that require full adsorption of wafers, large substrates and films.

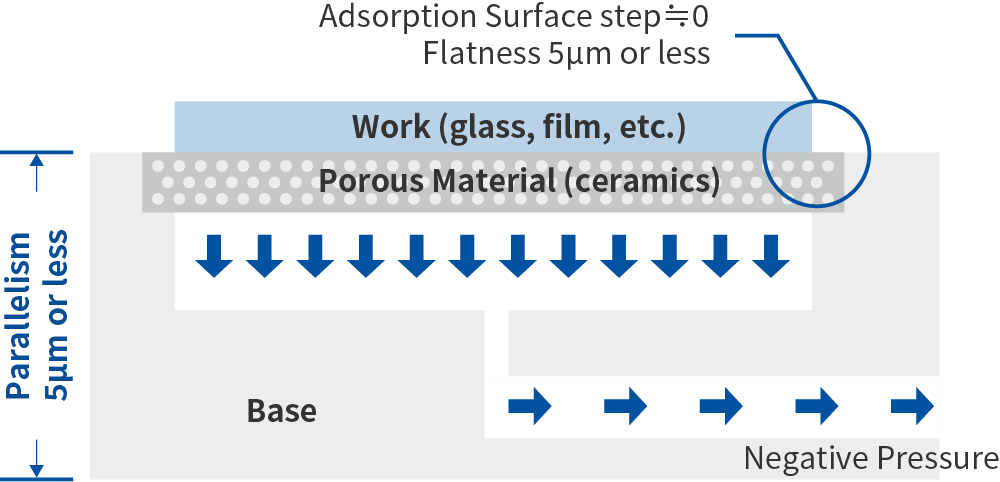

Structure

Structure of Porous Ceramic

Structure of Porous Ceramic

Structure of Porous Chuck (Vacuum Chuck)

Structure of Porous Chuck (Vacuum Chuck)

Production Example

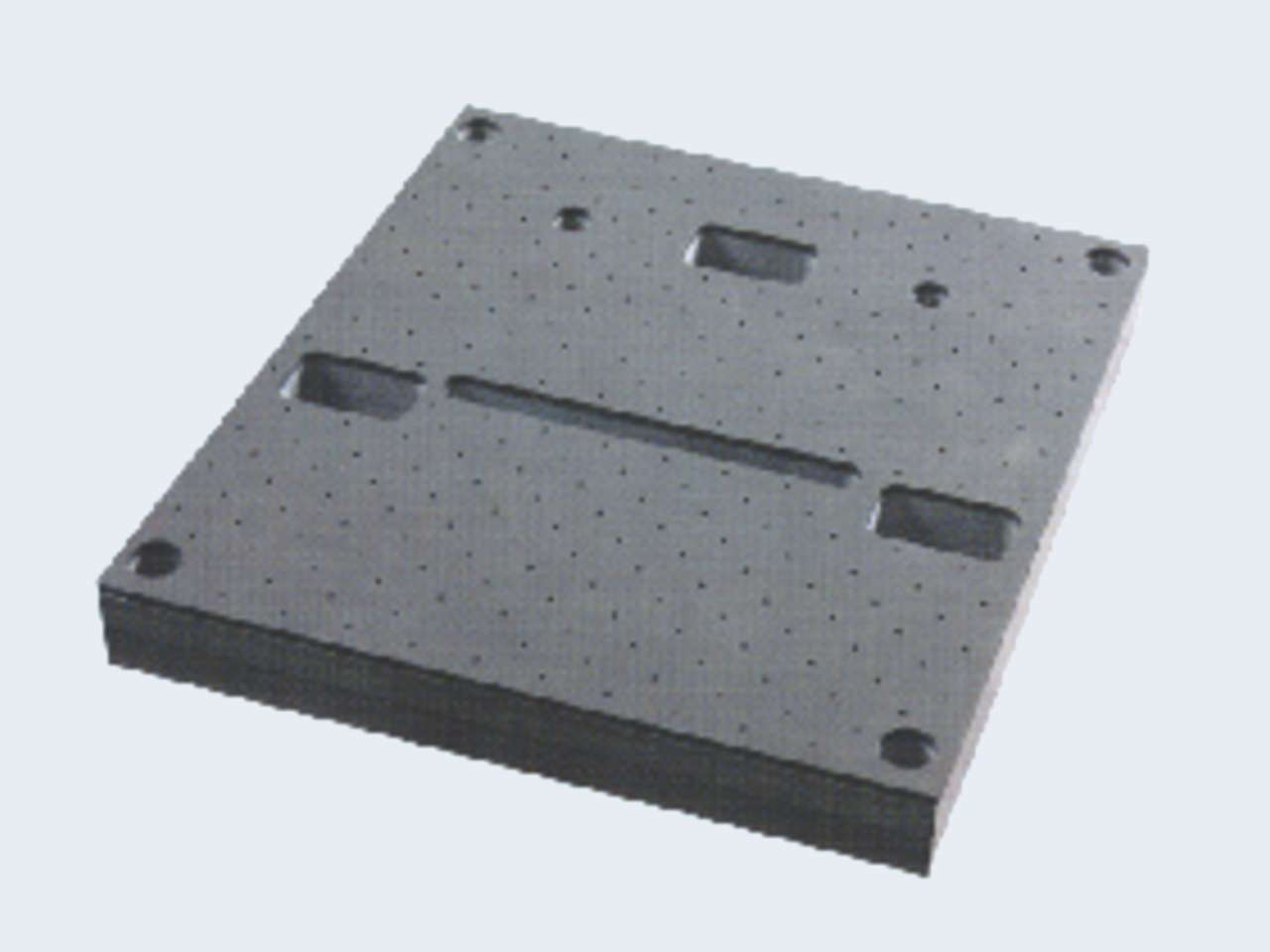

Precision Porous Chuck Table

By setting the θ axis in the center, the workpiece can be rotated and adsorbed to fix with high accuracy.

| Dimension | 1370x850x100 |

|---|---|

| Flatness | 10μm |

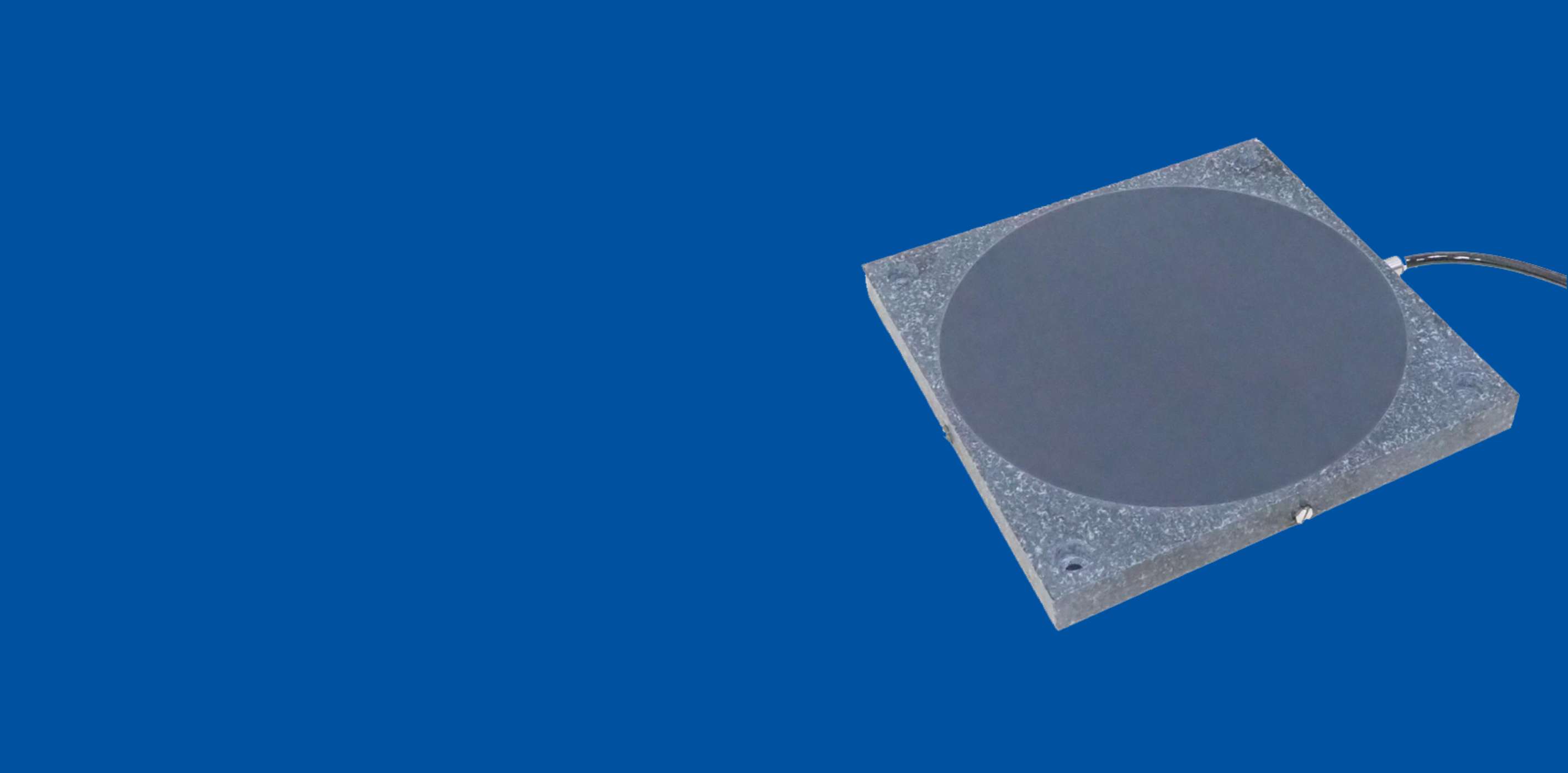

Circular precision porous chuck

Even if the workpiece is cut, it remains fixed by adsorption without shifting.

| Dimension | φ250x21 |

|---|---|

| Flatness | 3μm |

Non-Contact Precision Levitation Pad

High-precision, non-contact glass substrates can be transported.

| Dimension | 455x400x51 |

|---|---|

| Flatness | 5μm |

| Floating quantity | 30±5μm |

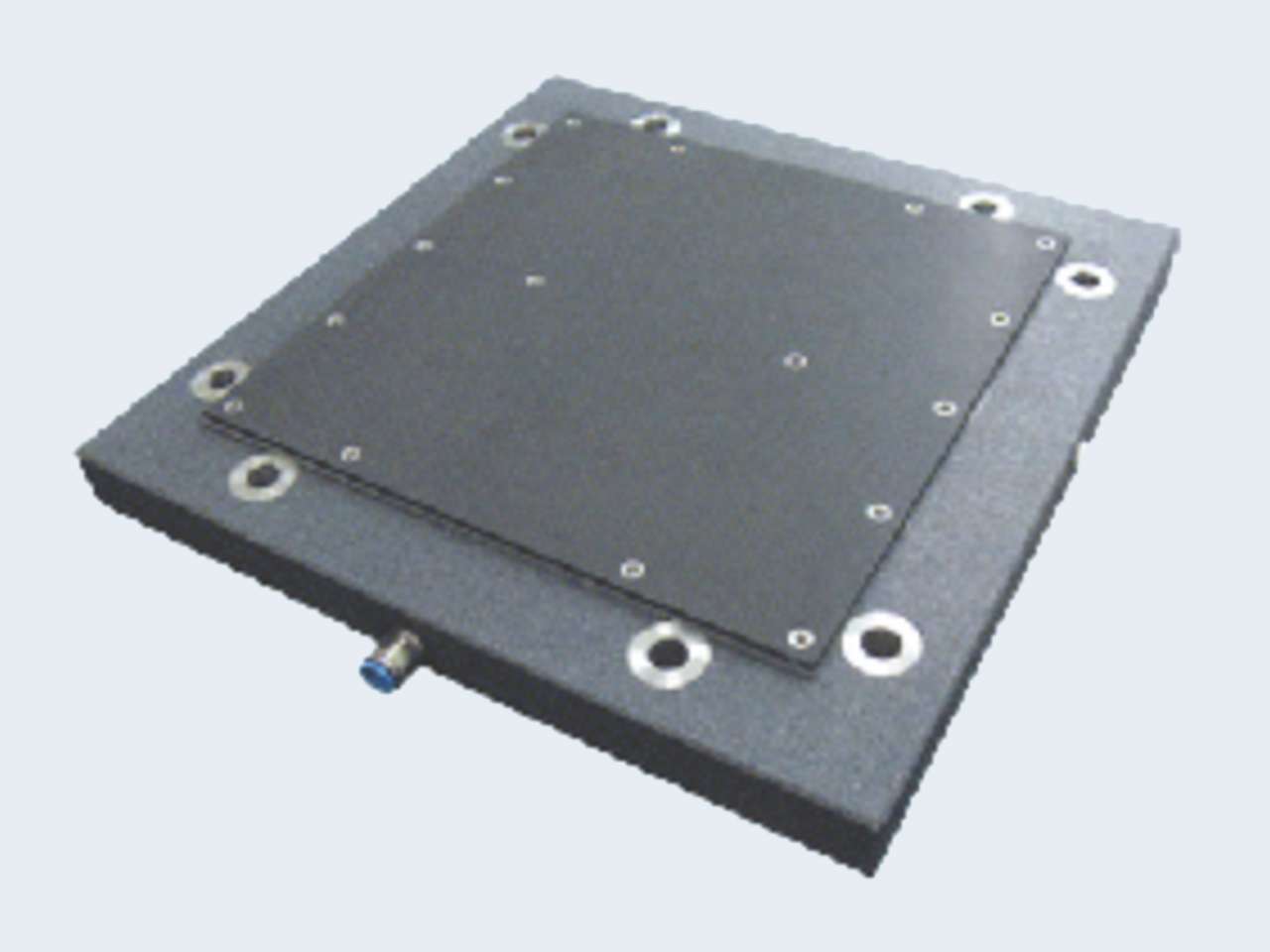

Glass film adsorption plate

With partial adsorption performance, workpieces smaller than the table can be adsorbed.

The use of porous materials with an average pore diameter of 2 microns prevents warpage and deflection even when the workpiece is made of film or thin glass.

| Stone dimensions | 390x390x40 |

|---|---|

| Adsorption part dimension | 300x300x5 |

The pore diameter of the porous body can be selected and it is possible to manufacture it in your requested size.

Please feel free to contact us first